Plant Maintenance & Services

Static and rotating equipment services such as Air-conditioning, AHU, Chillers, Boiler, Steam/Gas Turbine, Heat Exchangers, Cooling Towers, Compressors, Pumps, Dampers, Condenser, Generator Set etc.

Servicing and maintenance of control valve, transmitter, motor, electrical components e.g. switch gear, transformer etc.

Tank maintenance inclusive of tank cleaning, piping works, blasting & painting

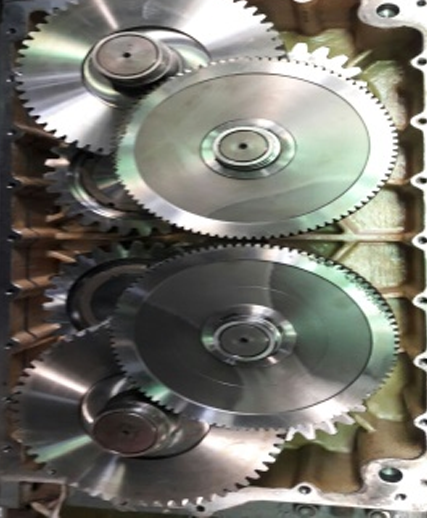

Preventive maintenance for plant equipment such as electric motor, pump, compressor, bearing system, generator set, etc. and also Condition Based Monitoring (CBM) – Vibration, Laser alignment, Thermograph, Balancing for any rotating equipment.

Plant maintenance and shutdown, i.e. equipment repairing jobs, refurbishment, major overhaul, part replacement and etc.

Steel Work Fabrication

VESB Engineering got a collaboration with local University on fabrication that required CAE (Computer Aided Engineering) or CAD (Computer Aided Design) which is VESB Engineering got permission to using CNC machine in the university such as CNC laser cut, CNC milling & lathe, CNC water cut, wire cut and RP machine.

Turnkey Project, Shutdown & Plant Modification

Incinerator Project: Developing waste incinerator with capacity 33 ton/day: Design, Fabricate, Construct & commissioning 1 complete unit waste incinerator (Project value : RM35 Million)

Sewerage Treatment Plant: Construct Sewerage Treatment Plant with capacity 43,500PE : Construction (Project value : RM5.55 Million)

Incinerator Plant Shutdown: Main contractor to perform INC shutdown : Dismantling, fabricate, installation and refurbishment of Incinerator plant. (Project value : RM805,000)

Cement plant Shutdown: Refurbish Electrostatic precipitator, crusher unit and Insulation works :Modification works (Project value : RM500,000)

Dryer Upgrading Works (Rubber Industry): Modification on the dryer system, to increase throughput capacity of production : (Project Value : RM500,000)

Shredder: Modification of cutting blade : to increase plant process capacity and efficiency of the shredder (Project Value: RM300,000)

Speciality / Expertise

Waste Incinerator:

- VESB Engineering have expertise to consult, design, construct, commission and operate the incinerator plant. We got many years of experiences dealing with incinerator plant. Till today VESB Engineering still support the industry that are using incinerator plant

- VESB Engineering are committed to develop our own Incinerator Technology by local expertise. To realize it, we already collaborate with local university in developing the technology and this is the second local waste incinerator in Malaysia

- VESB Engineering got a experience team to support Incinerator maintenance works

Shredder:

- VESB Engineering expert in developing and maintain the shredder unit. Many industries in Malaysia using shredder unit for as plant processing unit. We capable to fabricate the whole part of shredder even

perform custom work for the shredder.

- Fabrication of shredder part is required precision engineering machine such as CNC machine. Most of

the cutting work must using laser cut or water cut and machining work must using CNC milling or lathe.